Gerard, the instructions are a little misleading, but the next part talks about earthing the wiper contact and testing. I suggest you forget about the torque measurements since you haven't replaced anything electrical. (I assume)

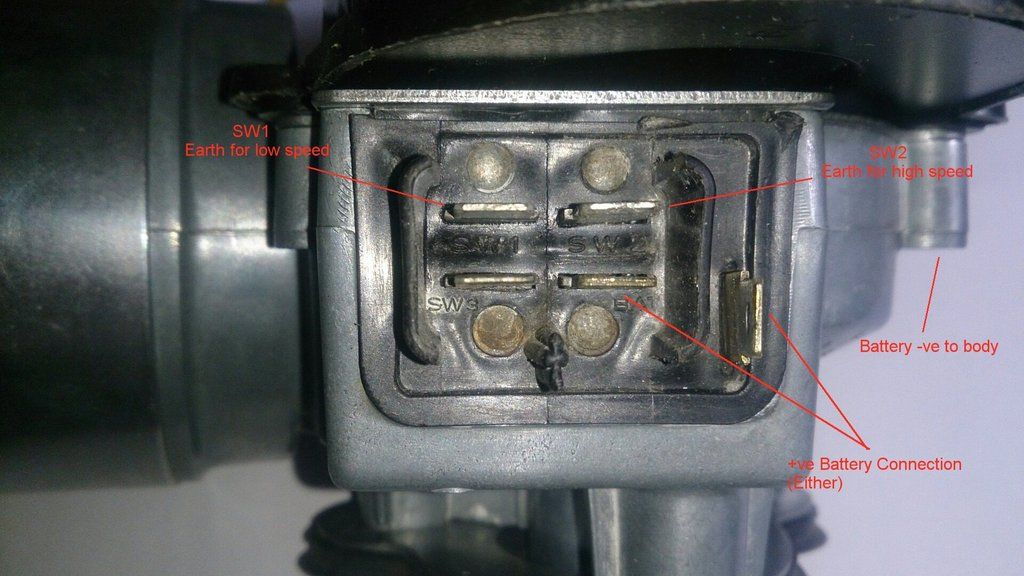

Connect the motor per the above picture. This is a picture of a Lucas plug as I don't have a Preslite to hand at the moment, but they should be the same, or very similar. Note that the terminals are marked inside the plug with Bat, SW1, SW2, and SW3.

1/ Connect the battery positive wire to either of the terminals shown, as they are connected together inside the motor housing. Don't connect it to the battery just yet.

2/ Connect the battery negative to the motor case.

3/ Connect one end of an additional wire, stripped by 3mm or less on one end and about 10mm on the other end to the motor case (with the 3mm end free), where you have connected the battery negative. If you don't have alligator clips or test leads, clothes pegs will work, or reinstall one of the mounting screws and clamp both wires under it. This wire will be used to simulate the operation of the wiper switch.

4/ Connect the positive wire from step 1/ to the battery +ve terminal. As you have noted, the motor will not run.

5/ Being sure to keep it clear of the battery positive connections, and keeping pinkies out of the way of the crank, touch the stripped end of the wire from step 3/ to terminal SW1. There will be a small spark, and the motor should operate at the lowest of its two speeds for as long as you leave the wire connected.

6/ Remove the wire from terminal SW1, allow the motor to stop, and touch it to terminal SW2. The motor should now operate at the higher of its two speeds.

7/ At some point in the above, check that the direction of rotation matches the arrow on the case. If it doesn't, check you have + and - around the right way on the battery and if all is well in the polarity stakes, you get to play musical magnets.

A couple of points.

-The crank is quite capable of munching up your fingers, so beware.

-If you must use a battery for your 12V source do try and arrange a 5 or 10A fuse in series with the positive lead in case of mishaps.

-With this simple test procedure the motor will not park itself in the same place every time, so when it is put in the car and the battery connected it will park itself, regardless of the wiper switch position, moving the wiper arms at a time you may not be anticipating. You might want to consider this.

- I notice there is a spot or burn mark on the outer contact, underneath the main drive gear. This is the park contact and it looks like there has been a recent mishap. The matching contact finger also looks blue, meaning it has been hot. It would be worth giving both a gentle polish with some fine glasspaper.

As far as the grease goes, the "1/3 full" bit means the third of the gearhousing where the worm and gear mate. As per your photo. It does no good anywhere else and is best not to get between the contact fingers and the sector ring under the main gear.

If you have access to a multimeter I can give you some other checks to do before powering it up.

Good luck.

Edited by user Tuesday, 20 October 2015 1:06:12 AM(UTC)

| Reason: Not specified